Research on perfume bottle design

Creativity and Design:

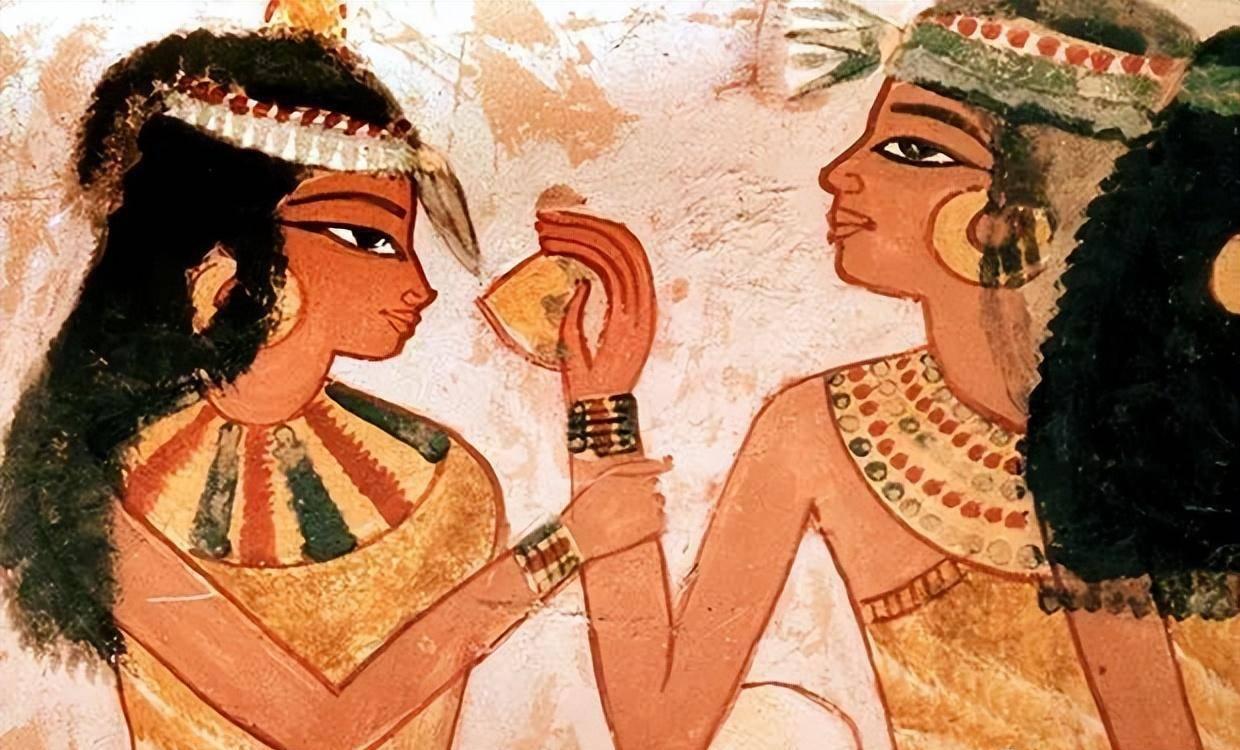

Brand story integration: designers can dig deeply into the stories behind the brand, such as the founder's experience, the origin of the brand, important moments in history, etc., and integrate these elements into the design of perfume bottles in an abstract or concrete way.

Art style reference: draw inspiration from various art genres, such as the color application of impressionism, cubist geometry, surrealist dreamlike elements, etc., and integrate the characteristics of these artistic styles into the design of perfume bottles.

Modern aesthetic trend: keep up with the fashion trend, pay attention to the current design trends, such as minimalism, retro style, futurism, etc., so that the design of perfume bottles keeps pace with the times and meets the aesthetic needs of modern people.

Shape and structure:

Asymmetrical design: Break the traditional symmetrical design, try asymmetrical modeling, and design more dynamic and modern perfume bottle.

Application of architectural elements: draw inspiration from architecture, integrate architectural features and elements such as arches, columns, spires, etc. into the design of perfume bottles, making perfume bottles more three-dimensional and structural.

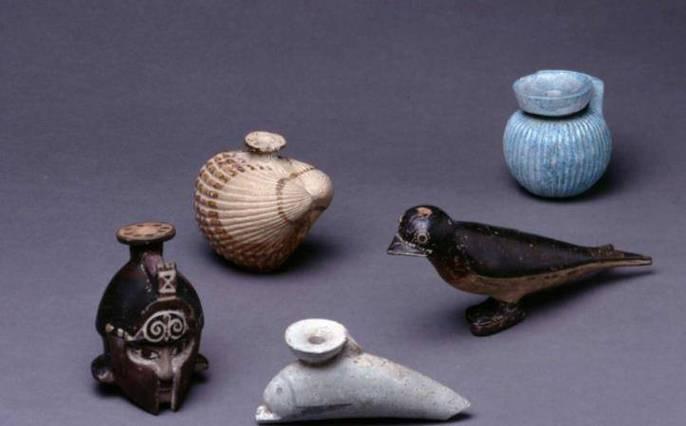

Natural form imitation: seek inspiration from the nature, imitate the form of natural objects, such as water drops, flowers, stones, etc., to make the design of perfume bottles more natural and smooth.

Color and Material:

Application of color psychology: according to the principles of color psychology, choose colors that can convey the temperament and emotion of perfume, such as warm orange, mysterious purple, fresh green, etc.

Special materials try: In addition to the common glass and plastic materials, you can also try to use metal, ceramics, bamboo and wood and other special materials to bring a new touch and visual effect to perfume bottles.

Environmental protection concept embodiment: When selecting materials, it is possible to consider using environmentally friendly and recyclable materials, reflecting the brand's environmental protection concept and social responsibility.

Detail handling:

Application of micro sculpture art: use micro sculpture art on perfume bottles to carve beautiful patterns and words, showing the brand's exquisite workmanship and unique charm.

Personalized label design: design unique label shapes, fonts and patterns to make the label of perfume bottles a beautiful landscape.

Add elements of limited edition: design unique elements and logos for limited edition perfume, such as special colors, materials, decorations, etc., to increase the collection value and uniqueness of perfume bottles.

The design of perfume bottle needs to comprehensively consider creativity, shape, color, material and details, so that the design not only conforms to the brand positioning and market demand, but also has uniqueness and attraction.