Beyond Cold How Our Insulated Fresh Bag Keeps Business Moving

Table of Contents

-

Why Freshness Matters More Than Ever

-

Cold Chain Without the Headache

-

The Insulated Fresh Bag at a Glance

-

The Layers That Do the Heavy Lifting

-

Built Tough for Everyday Delivery Chaos

-

Trusted by Chains, Traders, and Distributors

-

Customization That Speaks Your Brand

-

Our Factory Strength, Your Business Advantage

-

From OEM to ODM, A Partnership That Works

-

Looking Ahead in Cold Chain Innovation

1. Why Freshness Matters More Than Ever

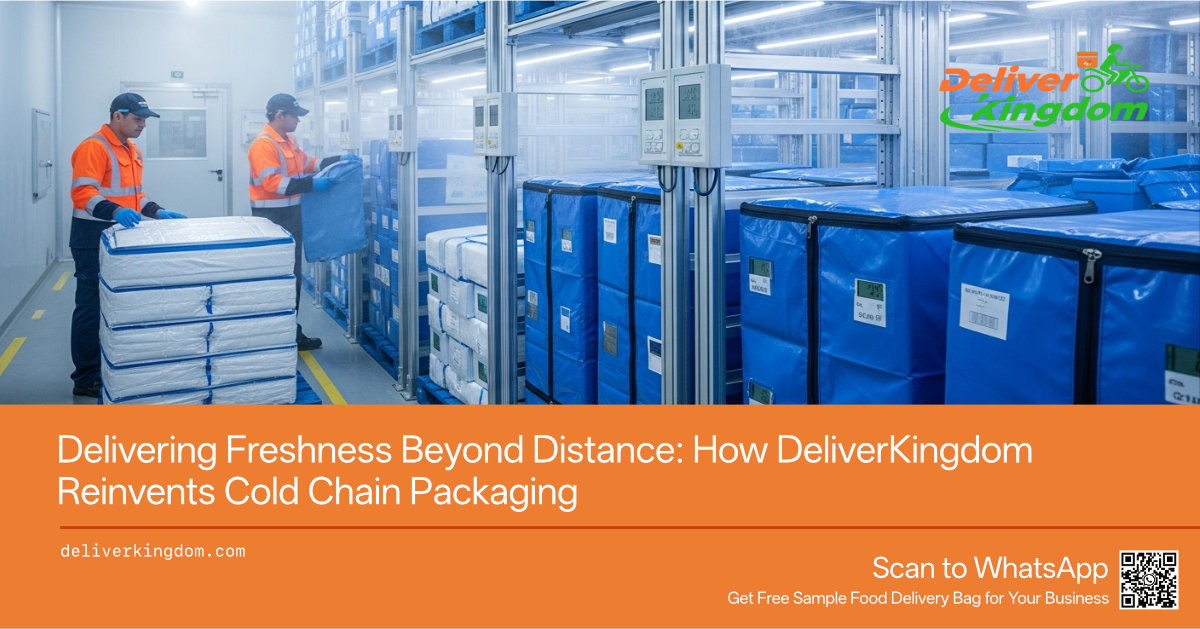

Food moves fast, customers want it faster. But freshness, that’s the deal breaker. At DeliverKingdom, we’ve learned one thing in ten years of cold chain packaging: there’s no shortcut to keeping food safe and fresh. That’s where our insulated fresh bag becomes not just a tool, but a lifeline.

2. Cold Chain Without the Headache

Deliveries can go wrong—traffic jams, heat waves, long hours on the road. Our insulated fresh bag is designed to handle all of that, keeping your goods safe from spoilage. It stands shoulder to shoulder with solutions like the vacuum insulated bag and deep cold box bag, giving companies a level of security they can actually trust.

3. The Insulated Fresh Bag at a Glance

Lightweight but surprisingly strong, waterproof, dust-proof, and resistant to smells—this bag does more than carry. It shields. Easy Velcro and zipper openings make it practical in the rush of a busy day, and when it’s not in use, fold it flat and save that warehouse space.

4. The Layers That Do the Heavy Lifting

Inside every insulated fresh bag, there’s a multi-layer design that traps cold and heat where it belongs. Long delivery times? No problem. Seafood, dairy, frozen desserts—they arrive just as they were packed. This is the kind of detail you only notice when your customer smiles instead of complains.

5. Built Tough for Everyday Delivery Chaos

We know the reality: truck doors slamming, bags stacked high, weather that doesn’t care about your deadlines. That’s why our insulated fresh bag and deep cold box bag are built for abuse, not just showroom photos. They last, they protect, and they make sure you don’t lose money on spoiled goods.

6. Trusted by Chains, Traders, and Distributors

Since 2013, DeliverKingdom has been working with restaurant chains, cold chain delivery firms, and global food logistics providers. Certifications like BSCI and ISO9001 prove our discipline, but what really wins trust is how consistently we deliver on massive orders, again and again.

7. Customization That Speaks Your Brand

No two businesses are the same. That’s why we don’t do one-size-fits-all. Choose your fabric, your dimensions, your colors. Print your logo big and bold on every insulated fresh bag or vacuum insulated bag we produce. It’s your brand, carried directly into the hands of your customers.

8. Our Factory Strength, Your Business Advantage

In Yangchun, Guangdong, we operate over 12,000 square meters of production space, powered by more than 400 skilled employees. From small trial orders to tens of thousands of bags, we can move fast without cutting corners. That’s how we’ve become a reliable OEM insulated bag supplier for partners worldwide.

9. From OEM to ODM, A Partnership That Works

OEM or ODM—it doesn’t matter where you stand. We design, we manufacture, we customize. Whether you need insulated fresh bag series or a deep cold box bag variation, we’re here to co-create a product that fits your exact business model.

10. Looking Ahead in Cold Chain Innovation

Cold chain logistics is changing, and DeliverKingdom is moving ahead with it. Lightweight, foldable, and tough—the insulated fresh bag is just one example of how we see the future. Reliable protection for your goods, more flexibility for your business, and a partner you can actually count on.