Are Hand Cream Tubes Recyclable? Understanding Eco Options for Brands

Consumers today care deeply about sustainability, and brands need to respond by making eco-friendly choices, especially in packaging. A common question is: are hand cream tubes recyclable? The answer varies based on the tube’s materials.

The Recycling Challenge of Traditional Tubes

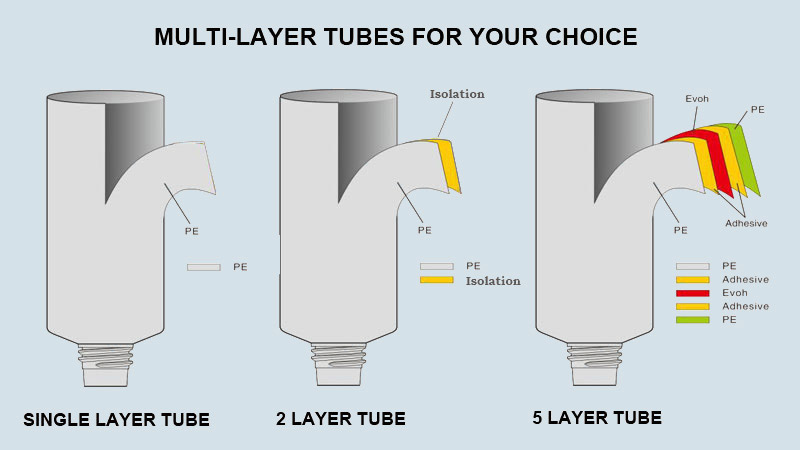

Many hand cream tubes on the market use multi-layered materials. Manufacturers combine different plastics or pair plastic with other substances to boost durability and barrier properties. However, this complexity creates a major recycling hurdle. Recycling facilities struggle to separate these mixed materials, often sending such tubes to landfills instead. As a result, traditional hand cream tubes contribute to environmental waste.

Sustainable Materials for Recyclable Tubes

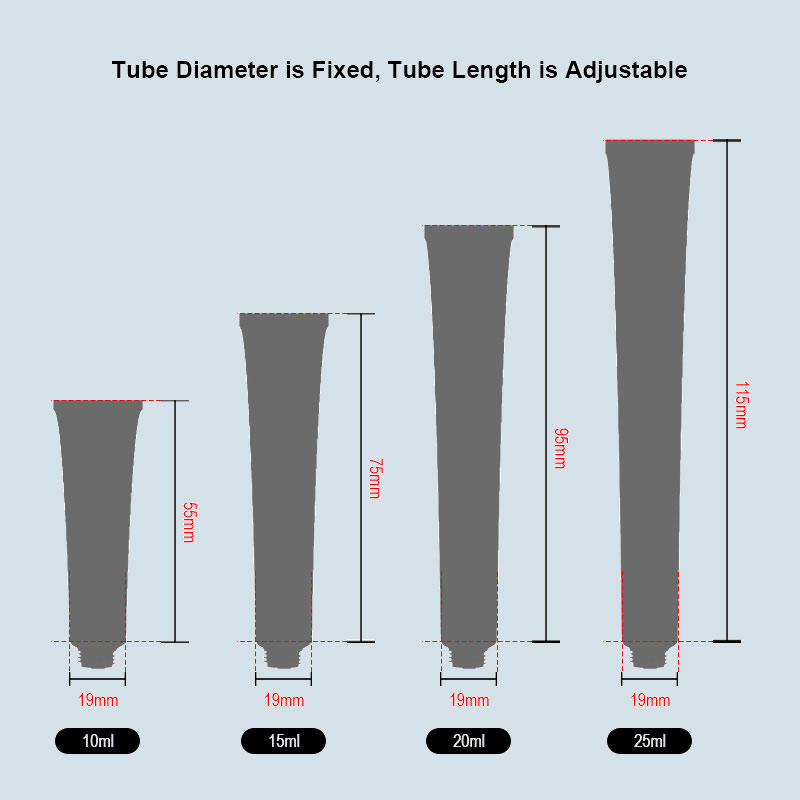

Forward-thinking hand cream tube manufacturers now offer better alternatives. Single-material plastic tubes simplify the recycling process. Since recycling plants can easily process one type of plastic, these tubes have a higher chance of becoming new products. Aluminum tubes are another great option. They are infinitely recyclable and retain their quality through repeated recycling cycles, making them an eco-friendly choice for brands.

How Brands Can Make a Difference

Brands play a crucial role in promoting sustainability. By partnering with a hand cream tube manufacturer that specializes in recyclable materials, brands can reduce their environmental footprint. Additionally, educating consumers about proper disposal methods through clear packaging instructions helps ensure recyclable tubes actually reach recycling facilities. Choosing sustainable packaging not only benefits the planet but also enhances a brand’s reputation among eco-conscious customers.