Top Trends in Cosmetic Emulsion tube Packaging for 2026

Top Trends in Cosmetic Emulsion Tube Packaging for 2026

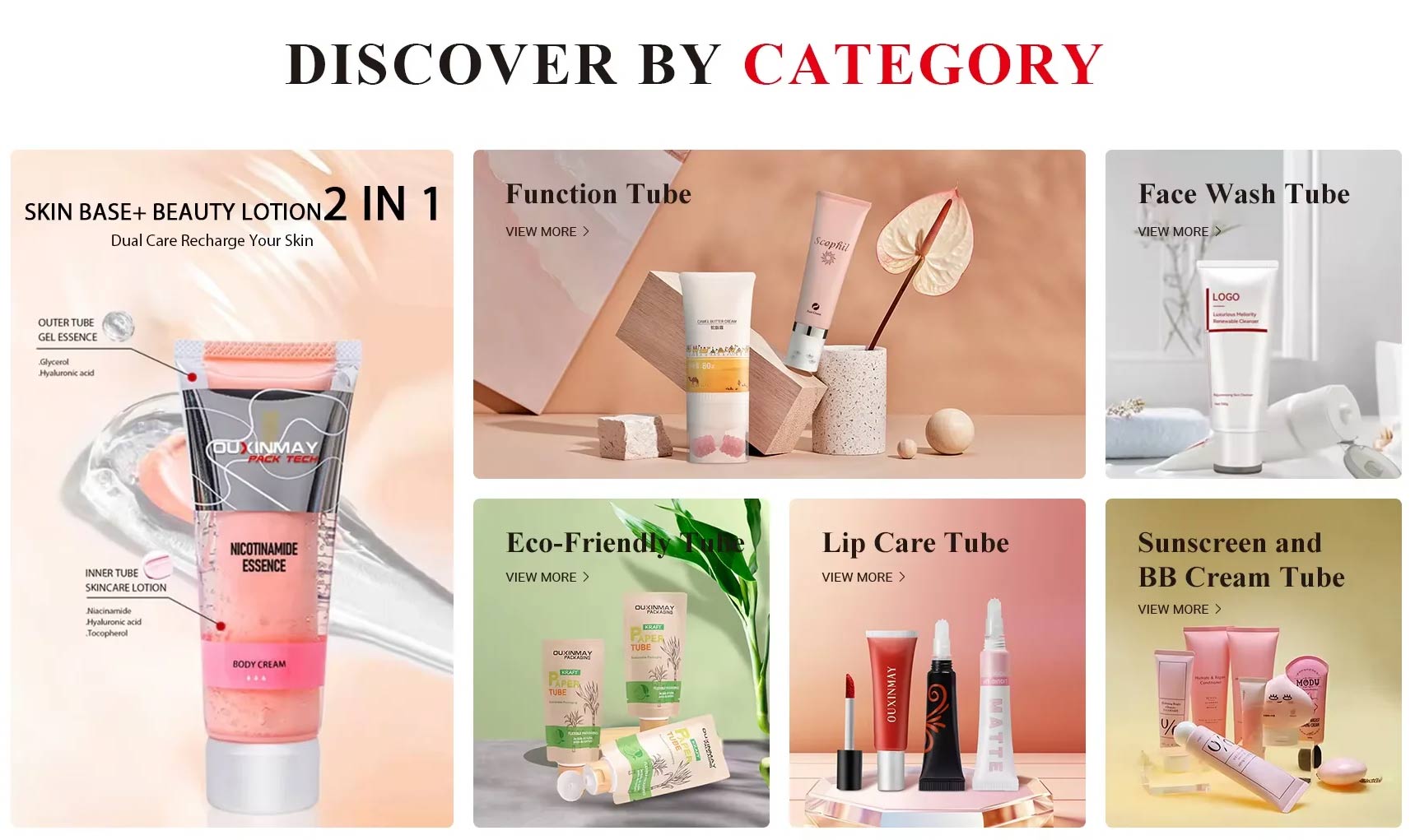

As the beauty and skincare industry continues to evolve, packaging innovation has become just as important as product formulation. Consumers in 2026 expect packaging that is functional, sustainable, visually appealing, and aligned with healthier lifestyle values. For cosmetic brands, keeping up with emerging packaging trends—especially in emulsion tubes, one of the most widely used formats for creams, lotions, and hybrid skincare formulas—is essential to staying competitive.

Below are the top trends shaping cosmetic emulsion tube packaging in 2026 from Runk, and how brands can leverage them to elevate product appeal and user experience.

1. Rise of Mono-Material Emulsion Tubes

Sustainability continues to drive major transformation in cosmetic packaging. In 2026, mono-material PE tubes have become a top choice for brands seeking recyclability and cleaner material separation.

Key advantages include:

♦ 100% recyclability within existing HDPE recycling streams

♦ Simplified structure without aluminum barriers

♦ Improved eco-conscious brand positioning

Brands aiming to achieve sustainable certifications or reduce packaging waste are increasingly adopting mono-material tubes for lotions, sunscreens, and emulsions.

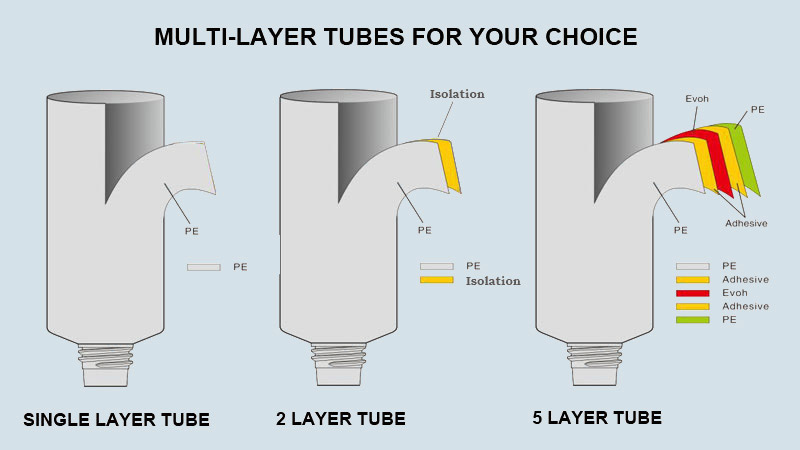

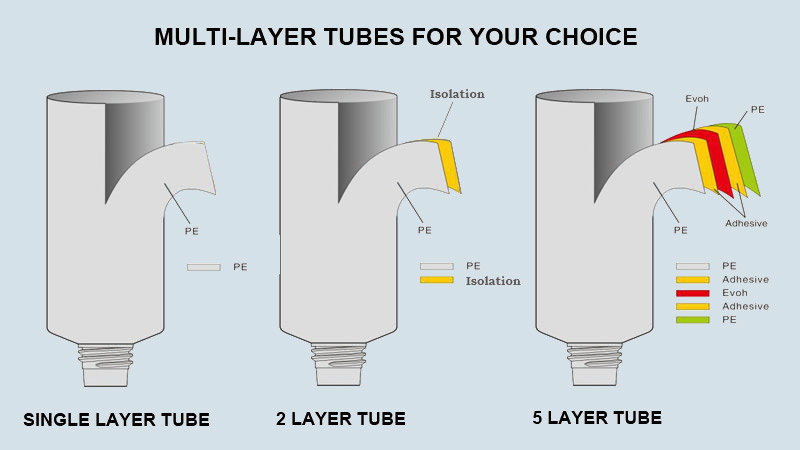

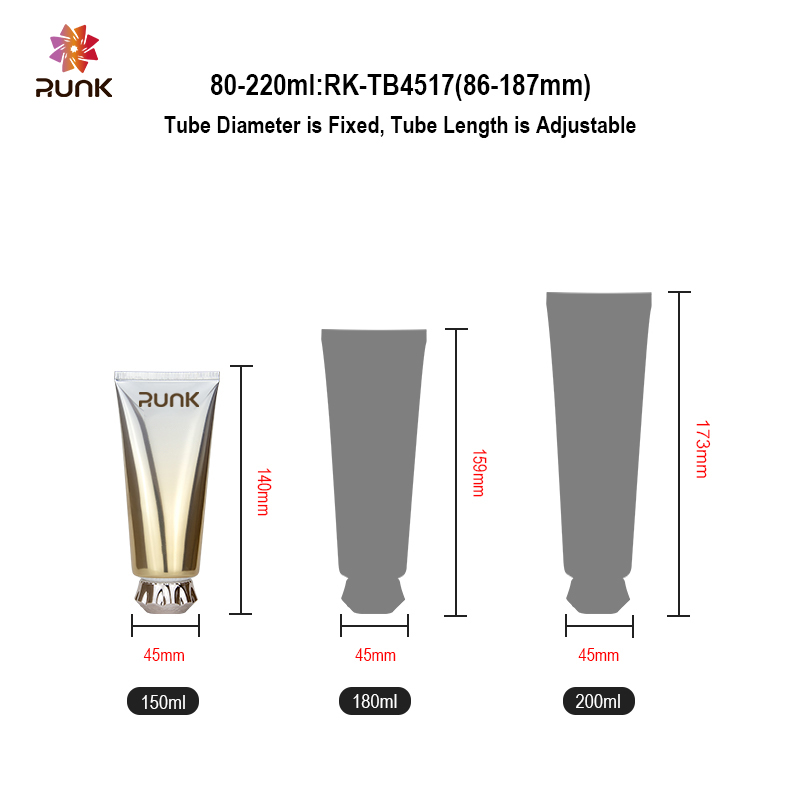

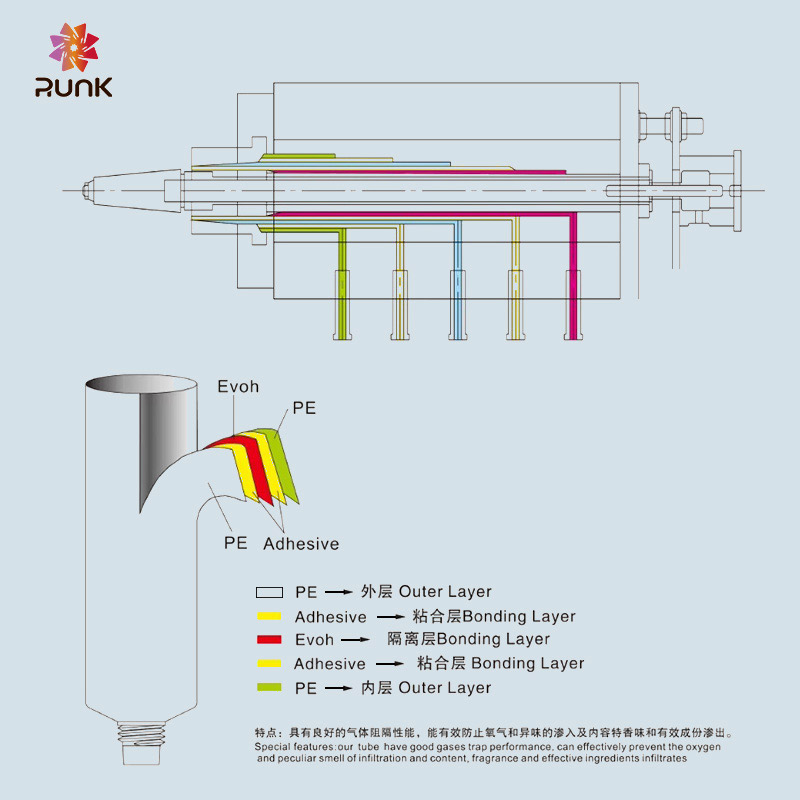

2. Enhanced Barrier Technology for Long-Lasting Formulas

While sustainability is a priority, brands also need packaging that protects delicate skincare formulas. Advanced EVOH barrier layers and multi-layer PE structures provide improved oxygen and moisture resistance without compromising recyclability.

This new generation of barrier tubes ensures:

• Active ingredients remain stable

• Longer shelf life

• Better product freshness and texture consistency

Barrier-enhanced emulsion tubes are especially popular among clean beauty and dermatology-focused brands.

3. Minimalist & Soft-Touch Aesthetics

The clean-beauty movement continues to influence packaging design. In 2026, minimalism remains dominant, with visual trends emphasizing:

♠ Soft-touch matte surfaces

♠ Neutral and muted color tones

♠ Simple typography

♠ Sleek curved silhouettes

These design cues communicate purity, premium value, and calmness—qualities increasingly sought after in skincare.

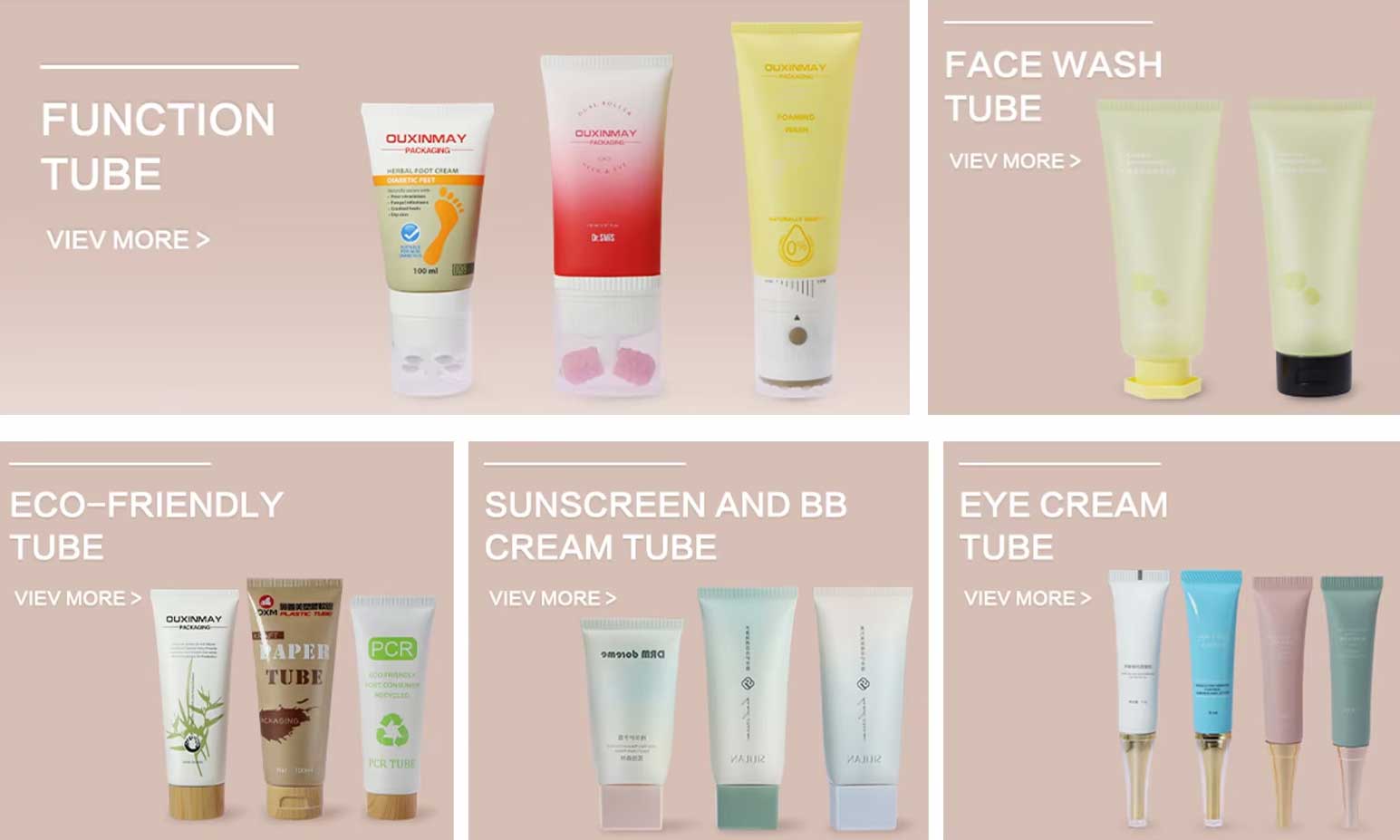

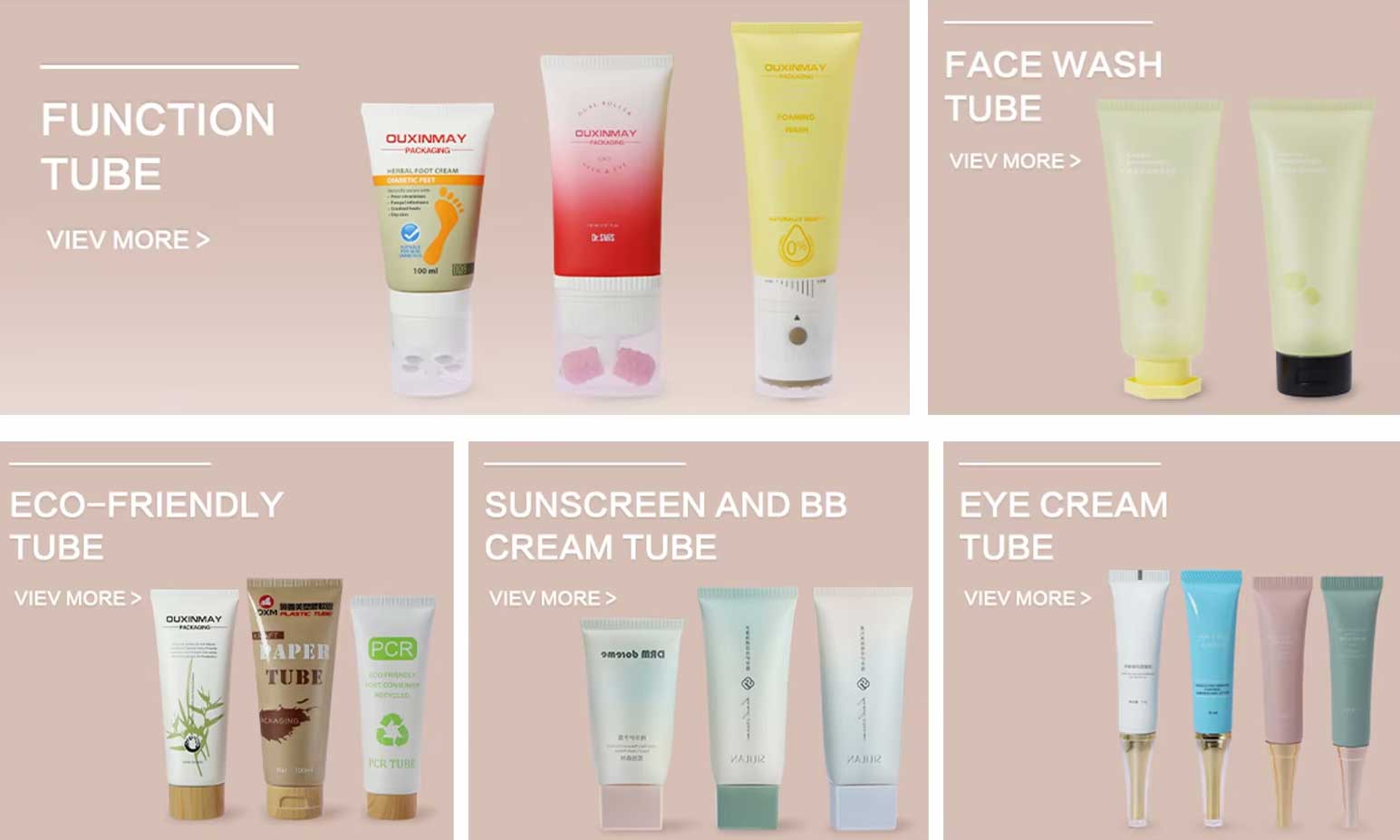

4. Precision Applicator Tips for Better User Experience

Consumers expect packaging that not only looks good but also enhances product application. Emulsion tubes with precision applicators are trending across multiple categories:

♥ Needle-nose tips for acne treatments and serums

♥ Metal roller applicators for cooling eye creams

♥ Silicone brush or spatula heads for masks and BB creams

♥ Custom-shaped massage heads for targeted skincare

These applicators improve hygiene, reduce product waste, and upgrade the overall user experience.

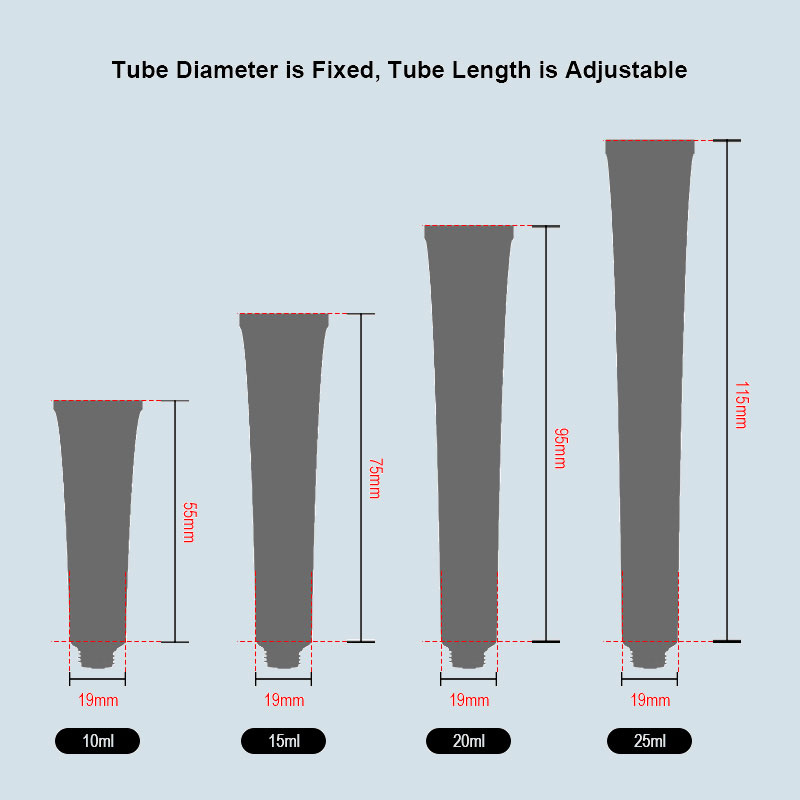

5. Increasing Demand for Travel-Friendly & Leak-Proof Tubes

As consumers resume global travel and carry-on beauty routines, portable and leak-proof tube packaging is in high demand. In 2026, brands are moving toward:

◊ Compact 15ml–50ml tube sizes

◊ Secure flip-top or threaded caps

◊ Durable multi-layer structures to prevent bursting

◊ Airline-friendly formats

Travel-size emulsion tubes are also ideal for sampling programs and subscription beauty boxes.

Conclusion

The cosmetic emulsion tube landscape in 2026 is shaped by sustainability, user experience, aesthetics, and personalization. Brands that embrace these packaging trends not only enhance product performance but also strengthen their market presence in a rapidly evolving industry.

Whether adopting mono-material tubes, upgrading barrier technology, or investing in elegant minimalist designs, the future of emulsion packaging lies in smart, clean, and modern innovation.